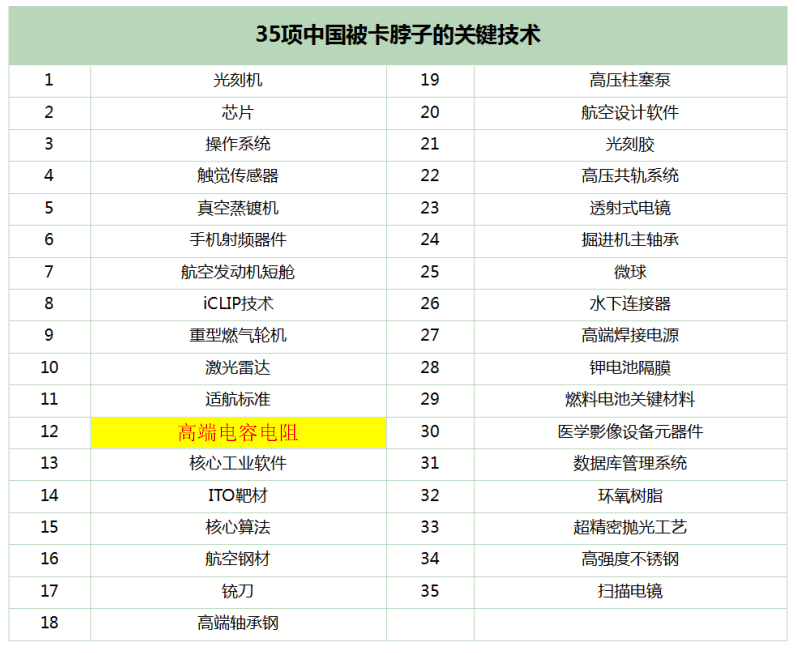

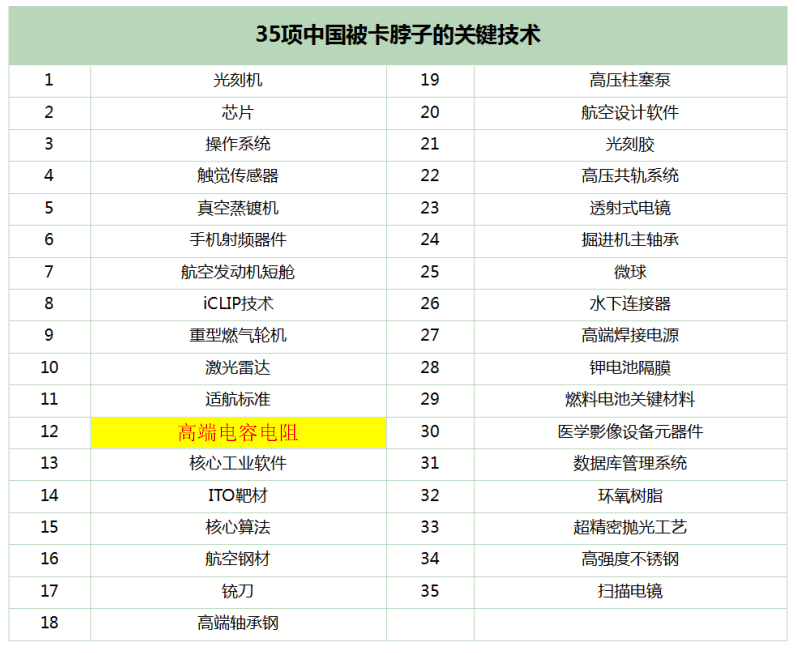

Five years ago, the news of the U.S. sanctions on ZTE came (April 16, 2018), and the whole country was in an uproar. Three days later, "Science and Technology Daily" launched a series of articles for three consecutive months, reporting 35 "stuck neck" technologies that restrict my country's industrial development, including chips, operating systems, tactile sensors, vacuum evaporation machines, medical imaging equipment components, etc. , involving many fields, has aroused widespread concern and discussion in the society, and since then has set off a wave of "stuck neck" technology in the scientific and technological circles!

Now that five years have passed, are those "stuck neck" technologies still stuck with us? After searching public information one by one and comparing authoritative information, at least 21 key technologies have been broken in my country, and other technologies are still being tackled or have not been fully disclosed due to other reasons.

Speaking of these key technologies that are stuck, many of us know that there are lithography machines and chips. In fact, it is far more than these key technologies. Let us take stock of a few key technologies that are not familiar to the public.

1. Underwater connector

This technology is probably one of the 35 core technologies that are most unfamiliar to the public. But when it comes to deep-sea manned submersibles, most technology enthusiasts will know that my country currently has three deep-sea manned submersibles, "Jiaolong", "Deep Sea Warrior" and "Struggle".

In November 2020, the "Struggle" manned deep submersible successfully dived to the bottom of the sea at 10,909 meters, setting a new record for China's manned deep diving. Behind this record breaking is related to Shanghai Lansuo Electronic Technology Co., Ltd., a private technology innovation enterprise in Shanghai. Through the independent research and development of the full-sea deep optical and electric watertight connector transmission components, Lansuo Technology helped the "Struggle" full-sea deep manned submersible and the "Canghai" full-sea deep video live broadcast lander in Mariana Trench joint operation successfully. In this 10,000-meter double-submersion mission, continuous and multiple full-sea deep engineering operations and practical applications have been achieved, and more than ten operations in water depths exceeding 10,000 meters have been accumulated, maintaining good stability of photoelectric signal transmission, and successfully completed " The 10,000-meter double submersible shooting and communication mission between the "Struggle" manned submersible and the "Canghai" live video lander. The success of this sea trial marks that my country's marine engineering technology has entered the world's leading level.

The underwater connector component is one of the very important components for the development of marine power. If all kinds of underwater equipment and instruments are compared to the terminal organs of the human body, the underwater connector component is like arteriovenous, spiritual network and key transmission center. It plays an irreplaceable role in the construction, operation and maintenance of underwater production and scientific research systems. With the construction of offshore oil and gas exploration and submarine observation network, the original "niche" underwater connector components have more stages.

The special features of underwater connectors are mainly reflected in three aspects, one is stable photoelectric transmission performance, the other is high water pressure resistance, and the third is tolerance in complex marine environments and comprehensive mechanical response. The development of the entire components should combine long-term technical succession and core breakthroughs, repeated experimental verification and a large amount of engineering experience accumulation.

Lansuo Technology is a provider of photoelectric transmission technology solutions. Its products are mainly used in optical and electrical data signals and power transmission between marine equipment systems and instruments.

According to public information, Lansuo Technology is a watertight connector transmission component and related marine engineering accessories independently developed by my country for the "Deep Sea Warrior" manned submersible and the "Struggle" full-sea deep manned submersible. The main domestic supporting units. Its core technical team has led the research and participated in a number of national key scientific research projects in the field of marine components, and has made breakthrough contributions to the development of domestic marine component technology.

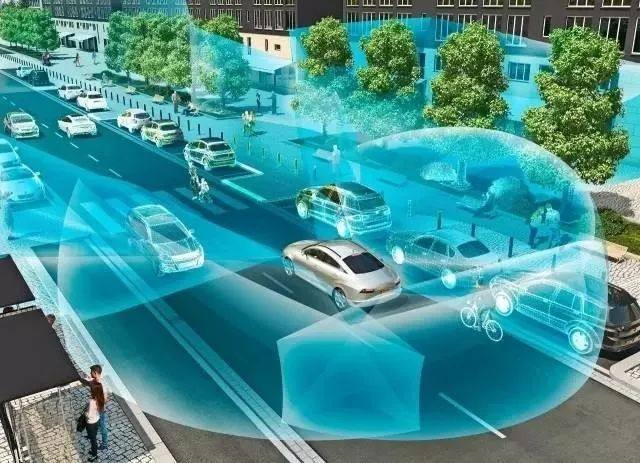

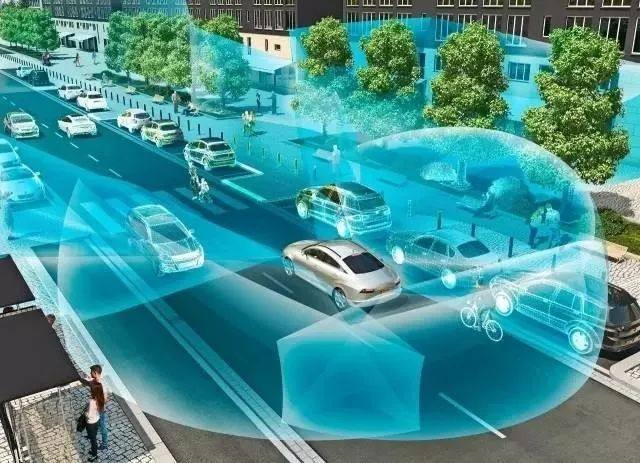

2. LiDAR

Lidar is a sensor with its own light source that actively emits laser light to sense the surrounding environment, just like bats use ultrasonic positioning. It is an essential component of self-driving cars and determines the evolution level of the self-driving industry. But in this field, five years ago, domestic products had almost no say.

Five years later, according to the "2023 LiDAR Top 10 Brand Ranking" launched by the CN10/CNPP brand data research department, the top ten brands are: VALEO (France), Hesai Technology (Shanghai) , Sagitar Juchuang (Shenzhen), Huawei (Shenzhen), LIVOX (Shenzhen), Innovusion (Suzhou), Velodyne Lidar (USA), OUSTER (USA), Yijing Technology (Beijing), Wanji Technology (Beijing). In other words, 7 of the top 10 are from China, which shows that our country has already caught up in this field.

In March 2023, RoboSense, a domestic lidar company, announced that its lidar MEMS galvanometer module has passed the AEC-Q100 certification, making it the only lidar scanning device in the world that has passed this vehicle-level certification. With the development of the market, Chinese brands may become the top of the list.

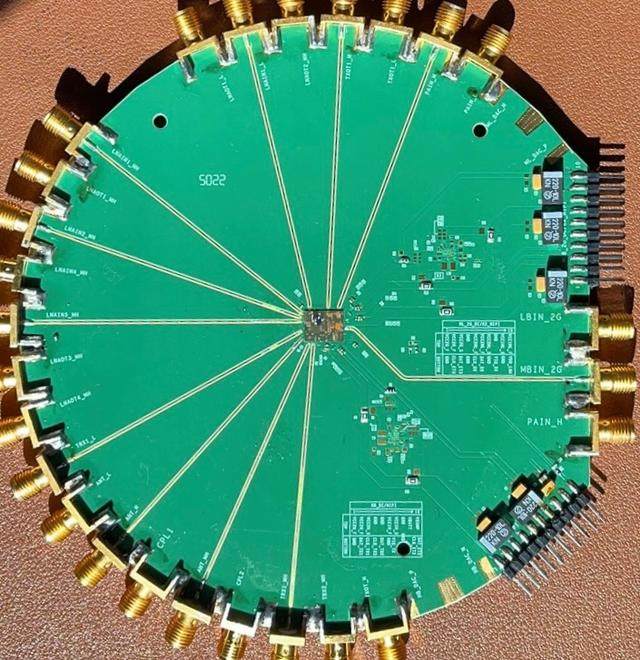

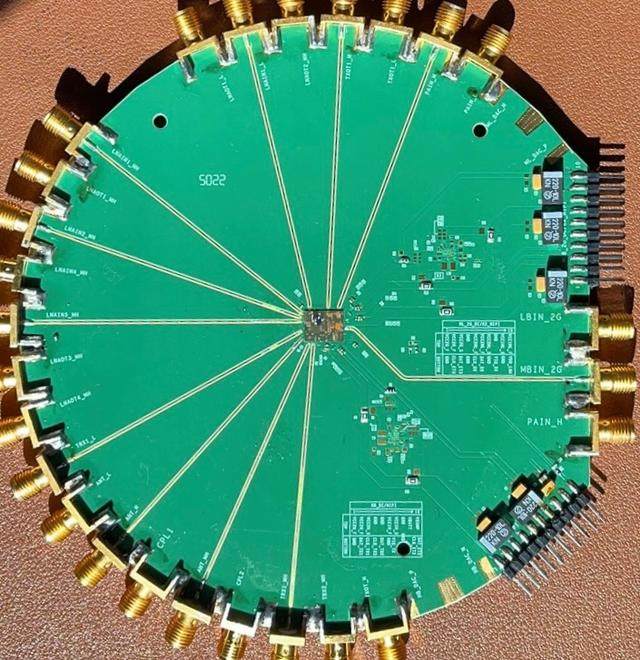

3. Mobile phone radio frequency devices

The radio frequency device of the mobile phone is like the radio soldier of the army, and the communication depends on it. China is the world's largest mobile phone producer, but five years ago, it could not manufacture high-end mobile phone radio frequency devices, which requires solid accumulation of materials, technology and design experience.

In 2018, the RF chip market was US$15 billion; the high-end market basically has no domestic products, and is monopolized by Skyworks, Qorvo and Broadcom, and Qualcomm also has a place. Over the years, the products of these companies have gained a good reputation and their performance is very stable. Therefore, major mobile phone companies such as Apple, Huawei, and Samsung basically use them.

Another key component of radio frequency devices - filters, the gap between domestic and foreign is even greater. The multi-billion dollar market for high-end filters used in mobile phones is entirely owned by foreign RF device giants such as Qorvo.

In March 2022, Fumanwei, a well-known semiconductor company in my country, announced that the 5G radio frequency chips that had been mass-produced before had begun to be supplied in batches. In addition, Huawei has also started selling mobile phone cases with 5G built-in radio frequency chips. This marks that my country has completely broken through the core technology of mobile phone radio frequency devices.

In March 2023, Shengxin Technology, a domestic RF module solution provider, announced the launch of a new generation of highly integrated RF front-end module (Phase8 L-PAMiD) product FCX62985, which is the first Phase8 L-PAMiD in China. L-PAMiD is an RF front-end chip that integrates multiple channels PA/LNA/filter/multiplexer/switch and controller. It is the most valuable and most difficult part of the RF front-end market. The high-end models and flagship phones of mobile phone terminal manufacturers all need L-PAMiD products, and brand customers pay more attention. Industry commentators believe that the launch of the FCX6298 chip has ended the blank of domestic substitution of high-end RF front-end chips.

4. Main bearing of roadheader

The whole world knows that China is an "infrastructure madman", and the manufacturing capacity of the most important heavy equipment of a big country in infrastructure projects, the "full-section tunnel boring machine" (also known as "shield machine"), is also close to the world's most advanced level. , however the most critical main bearings all rely on imports.

The main bearing is known as the "heart" of the roadheader. It bears the main load during the operation of the roadheader and is a key component of the cutter head drive system. The working condition is very bad. In the closed underground working space, the main bearing also generates frictional heat due to long-term continuous operation, and the temperature rises from 20 degrees Celsius to 120 degrees Celsius. This kind of working condition has very strict requirements on the reliability index of the main bearing of the roadheader.

Due to the high technical content, the cost of a single main bearing accounts for about 1/20 of that of the roadheader, and is the most valuable of all the parts of the roadheader.

In 2018, there were only four companies in the world capable of developing main bearings for roadheaders, namely Rothe Erde, IMO, FAG in Germany and SKF in Sweden. Among them, Rothe Erde occupies the global full-section tunnel boring machine field most of the market share.

In April 2022, my country's first nationally produced 3-meter-level main bearing shield machine "China Railway No. 872" designed and manufactured by China Railway Equipment broke ground in Suzhou, marking my country's first nationally produced 3-meter-level main bearing shield machine Successfully completed the underground excavation task.

In order to solve the "stuck neck" problem of the main bearing of the roadheader, as early as 2015, China Railway Equipment Co., Ltd. and the leading domestic main bearing and reducer technology enterprises - Luoyang LYC Bearing Co., Ltd. and Zhengzhou Machinery Research Institute formed the "national team". , take the lead in tackling difficulties. In May 2020, the first batch of domestically produced 6-meter-class conventional shield TBM 3-meter-diameter main bearings and reducers passed the test and inspection, marking a major breakthrough in the localization of the core components of my country's shield machine.

The successful application of "China Railway No. 872" in Suzhou Rail Transit Line 6 has verified the stability and reliability of the main bearing of the domestic shield machine, marking a key step towards the comprehensive promotion and use of the main bearing of the domestic shield machine.

According to reports, China Railway Equipment closely follows the deployment innovation chain of the industrial chain supply chain, and actively builds a key common innovation platform for the coordination and linkage of upstream and downstream industries. At present, it has overcome the 3-meter-level main bearing, large displacement pump, main drive seal, and programming control. A number of key core technologies of the tunnel boring machine "stuck neck" such as PLC, completed the application of 41 sets of samples on the construction site, and enhanced the independent controllability of the industrial chain and supply chain.

In addition to the above-mentioned ones, the "stuck neck" technologies that have been conquered by our country or basically realized domestically and are no longer subject to foreign countries include: chips, operating systems, tactile sensors, vacuum evaporation machines, heavy-duty gas turbines, ITO targets, aviation steel materials , high-end bearing steel, high-pressure plunger pump, high-pressure common rail system, microspheres, key fuel cell materials, high-end welding power supply, lithium battery diaphragm, ultra-precision polishing process, database management system, scanning electron microscope.

Of course, in some fields, we are still unable to reach the world's most advanced level, but we have already achieved from 0 to 1, then from 1 to 10, to 100, it is also inevitable for technological development. After all, we ourselves are a huge demand The market can continuously promote the development and progress of technologies in various fields, and ultimately allow all technologies to advance to the top of the world!

Article source: Science and Technology Daily

Language

Language

CN

CN

Home 》

Home 》

Service hotline

Service hotline WeChat Service Account

WeChat Service Account  WeChat Public Account

WeChat Public Account  Official Website

Official Website  Tik Tok

Tik Tok  Video Number

Video Number