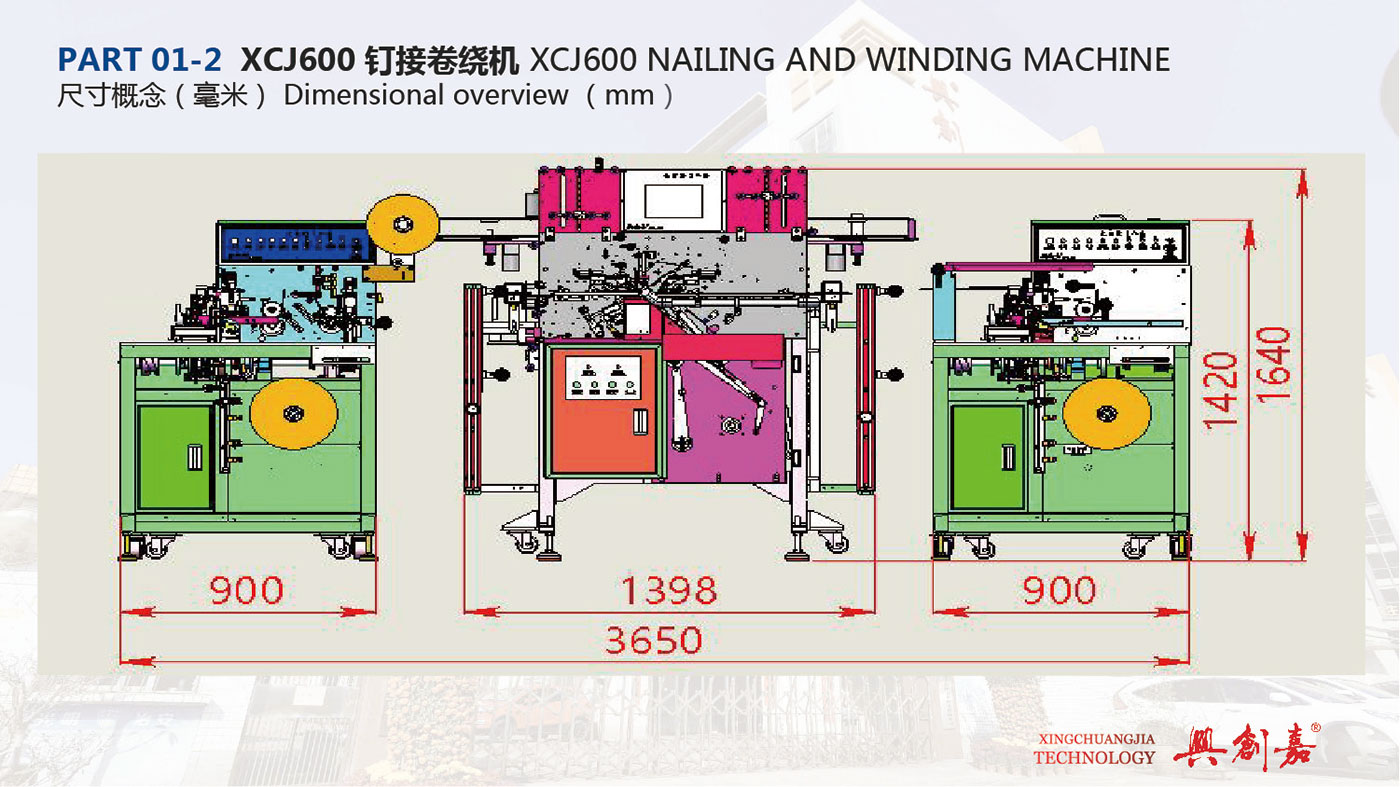

1. Specifications of materials used:

(1). Material outer diameter: positive and negative foil ∮245mm, electrolytic paper ∮330mm, special tape ∮240mm.

(2). Material inner diameter: positive and negative foil ∮40mm, electrolytic paper ∮40mm, special tape ∮150mm.

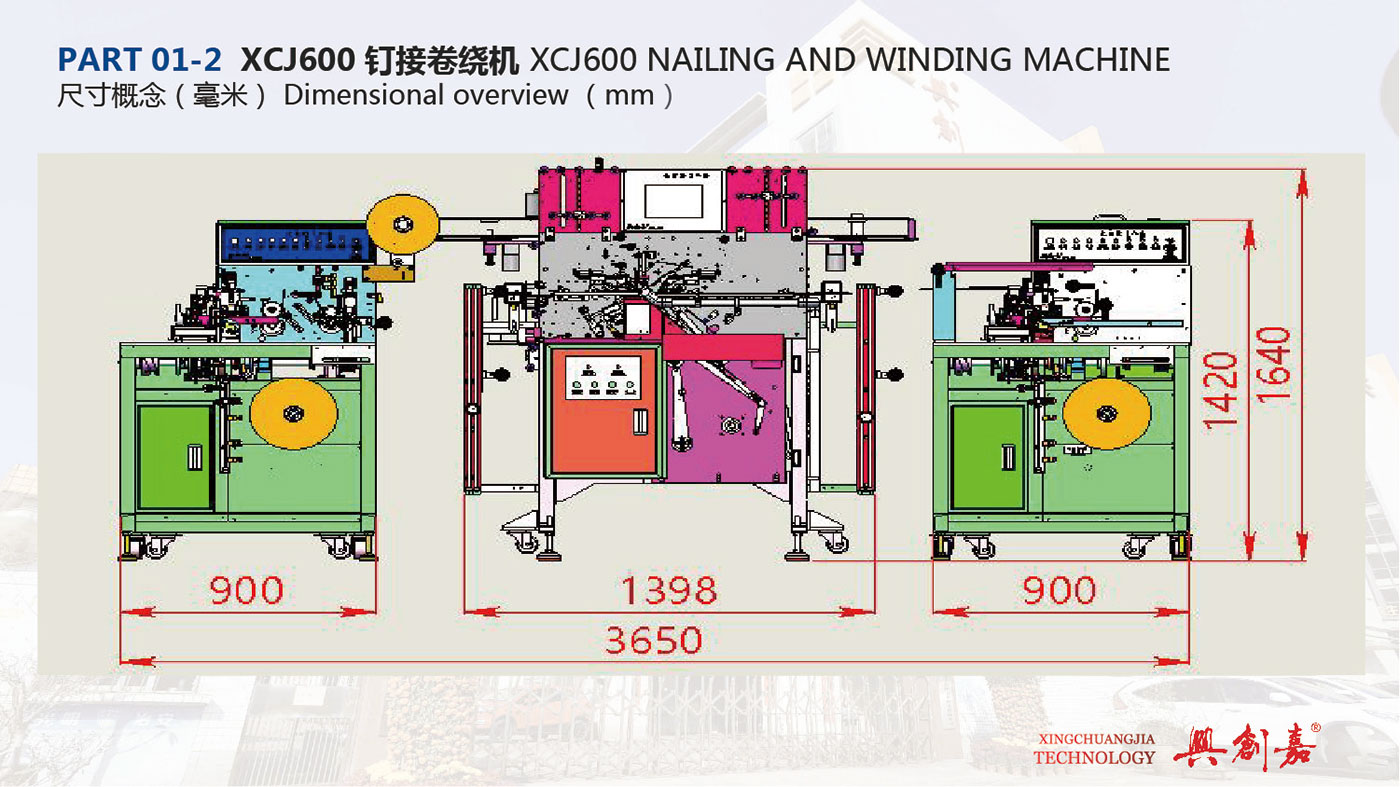

2. Equipment template specifications:

(1). Needle diameter: ∮0.5, ∮0.6, ∮0.8, ∮1.0.

(2). Template hole distance: 0.92, 1.2, 1.5, 2.0.

(3). Square hole size: 0.7*0.7, 0.8*0.8, 0.85*0.85, 0.92*0.92, 1.1*1.1.

3. Production process parameters:

(1). Product outer diameter (diameter) range: D=φ6.3mm-φ10

(2). Needle diameter range: φ1.8-φ3.0.

(3). Height range of cell products: b=4-20mm (different specifications can be replaced)

(4). Width range of termination tape: 3-10mm.

(5). Pole piece cutting method: cutting with a knife, the burr of the pole piece is less than 30um

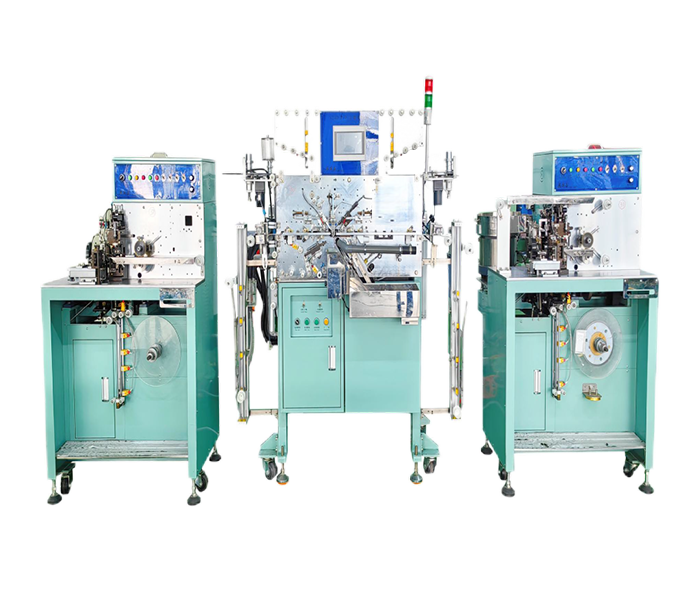

4. Standard functional configuration of mechanical equipment:

Two layers of paper, tape after winding, glue termination, aluminum foil punching before positive foil riveting, servo motor power for nailing machine, flat die for nailing and winding machine, touch screen, split conveying aluminum foil table device (detachable), short circuit detection , Positive and negative scissors, positive and negative abrasives, nailing and dust removal, a total of 4 stations, foil plate track and bearing synchronization, horizontal feeding random needle detection, riveting thickness detection, cylindrical horizontal feeding.

5. Equipment optional function:

(1). Pad negative foil function

(2). Tape joint automatic removal function

(3) Negative outsourcing function

(4). Curved mold function (the curved mold can properly reduce the outer diameter of the core bud and reduce the short circuit rate of the product).

(5). 4-layer paper function

(6). Guide pin automatic feeding

(7). Bending needle detection

(8). Needle roll support shaft device

Language

Language

CN

CN

Home 》

Home 》

Service hotline

Service hotline WeChat Service Account

WeChat Service Account  WeChat Public Account

WeChat Public Account  Official Website

Official Website  Tik Tok

Tik Tok  Video Number

Video Number