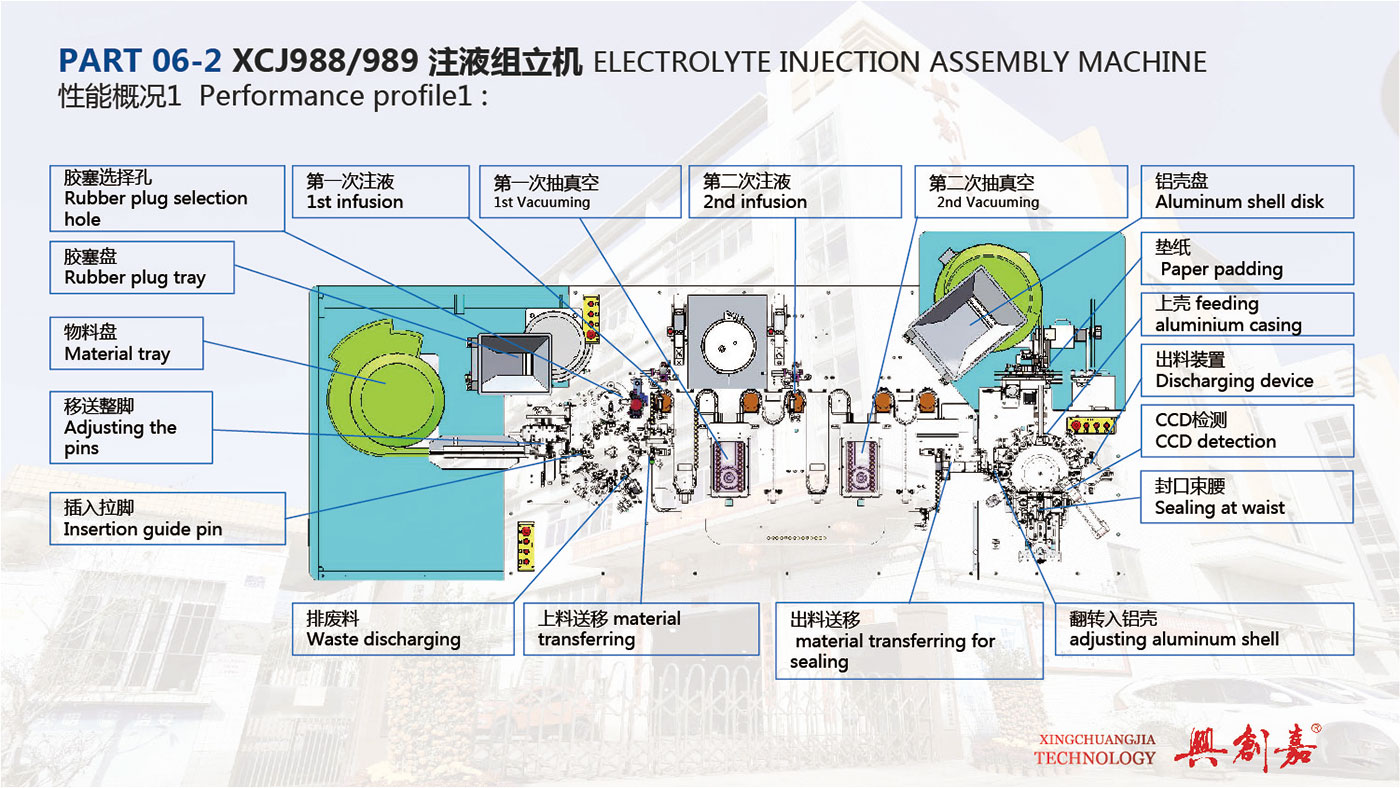

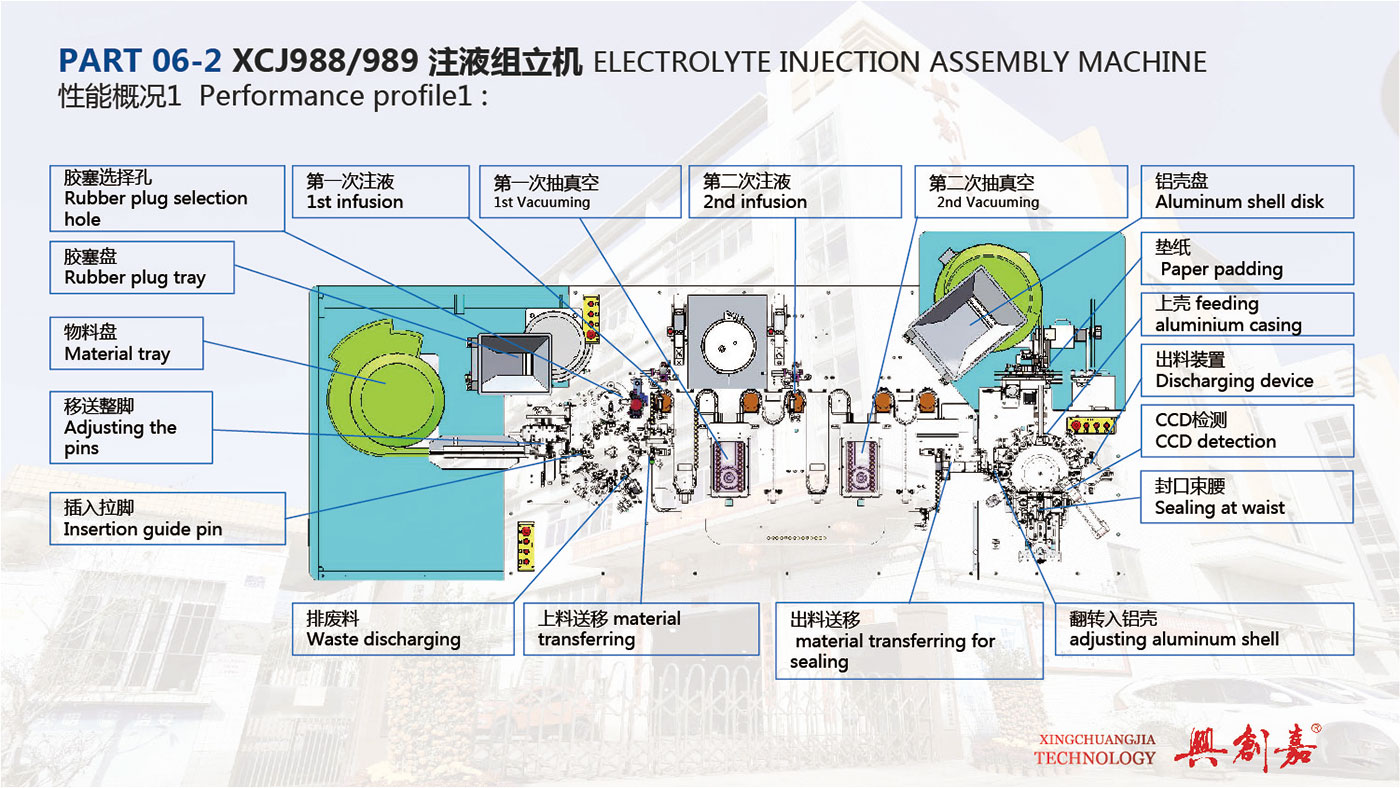

1.The dry core, rubber plug and aluminum shell are fed through the vibrating plate or the device can also be connected to the NAILING AND WINDING INTEGRATED MACHINERY).

2. The equipment will assemble rubber plugs and and cell together and transfer them carriers with18 groups of chain (14 products in each group of type 988 and 11 products in each group of Type 989). The carriers will transfer the products to the liquid injection station for injection. After the completion of liquid injection, the two groups of products enter the empty tank together for vacuum treatment. The vacummed products are driven to the 2nd liquid injection. The twic injected and vacummed product will be sent by robotic arms for assembling and sealing with aluminum shells.

3. The cell and aluminum shell are preheated during transportation.

4. Non-contact photoelectric positioning is adopted for the hole of the rubber plug.

5. The leads of the core are perforated through the rubber plug, and and inserted to the core directly by robotic arms with core and rubber assembly space and placeholder for CCD detection station.

6. The equipment adopts 12 fixed girding stations.

7. Guild pin and polarity adjustment are carried out at the station before sealing and waist binding.

8. Discharge mode: NG product first and then good product, 989 model is avaiable for either way of discharge first.

9. Realtime size detection of products.

10. With girding station cleaning function.

11. Aluminum shell paper padding is optional.

Language

Language

CN

CN

Home 》

Home 》

Service hotline

Service hotline WeChat Service Account

WeChat Service Account  WeChat Public Account

WeChat Public Account  Official Website

Official Website  Tik Tok

Tik Tok  Video Number

Video Number