-

-

Aluminum Electrolytic Capacitor Production Equipment

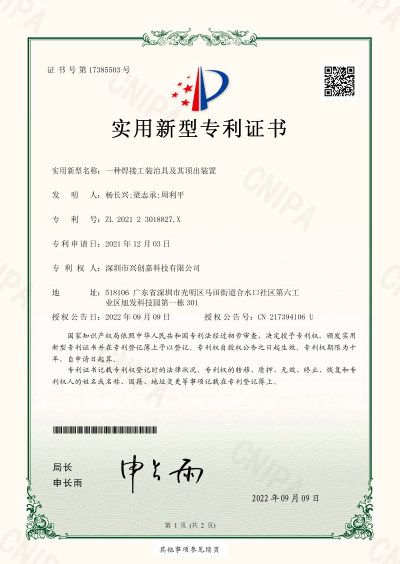

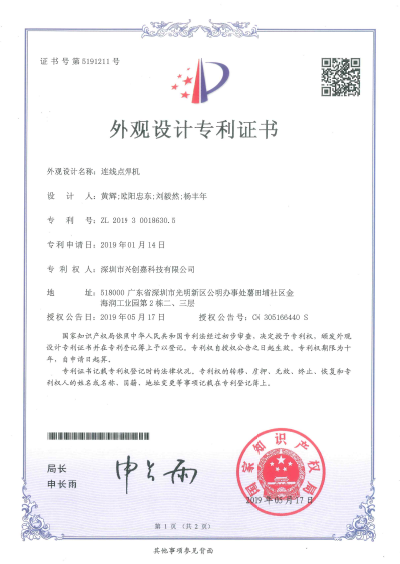

Lead TypeXCJ600 Nailing and winding machine XCJ600T Nail and roll all-in-one machine XCJ880Z Automatic assembly machine XCJ880ZC Liquid injection machine XCJ880ZTP SMT assembly machine XCJ988/989 Liquid injection machine XCJ2280Z Automatic assembly machine XCJ2500ZB Automatic assembly machine XCJF-B Semi-automatic sealing machine XCJ880T Automatic casing machine XCJ1200TB Automatic casing machine XCJ1200TC Automatic casing machine XCJ2280T Automatic casing machine XCJ18YZ Printing machine XCJZB Seat board machine XCJSW-DR02-A Appearance Inspection Machnie for aluminium electrolytic capacitors and supercapacitors XCJ2500QX5 Washing machineSolid TypeXCJ600T Nail and roll all-in-one machine XCJDL Connection spot welding machine XCJDH Automatic spot welding machine XCJHZ Automatic formation machine XCJJZD Automatic monomer impregnation machine XCJJZY Automatic oxidant impregnation machine XCJJZF Dispersion impregnation machine FTF-465 Tunnel furnace XCJZRB Solid state sealer XCJ18YZ Printing machine XCJZB Seat board machineHorn TypeXCJ3500S Automatic feeding machine XCJ3500M Automatic riveting machine XCJ3500Z Automatic bending machine XCJ3500SMZ Feeding riveting cover bending machine XCJ3500F Automatic sealing machine XCJ3500T Automatic casing machine XCJ3500C Ultrasonic welding production line XCJ3500MJ Laser welding production line XCJ3500AHB Production line XCJ4500 Production line XCJ3500CDZ Injection Production Line

-

Super Capacitor Production Equipment

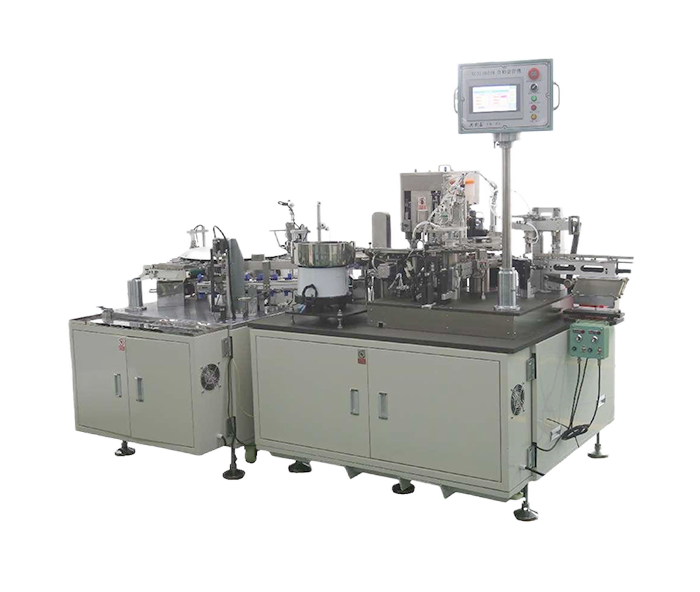

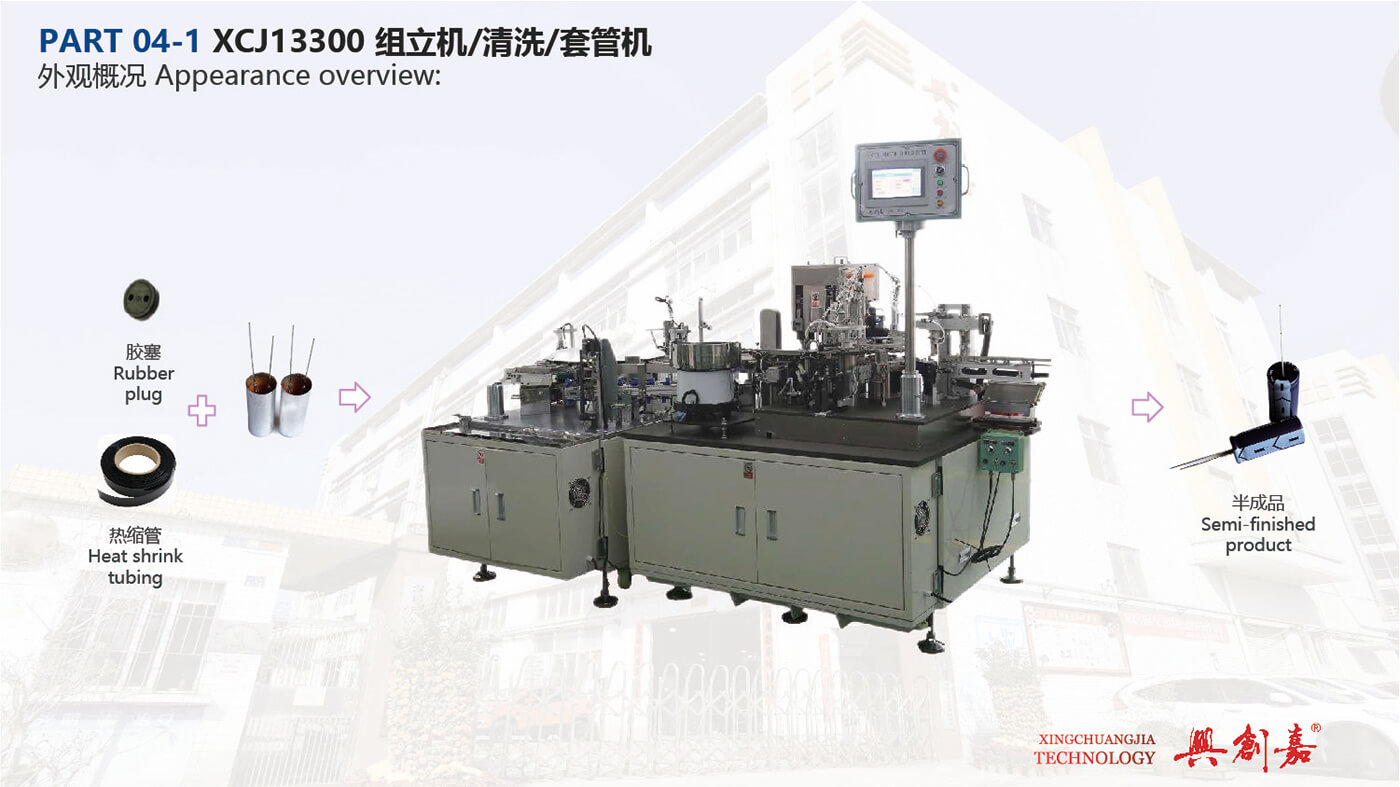

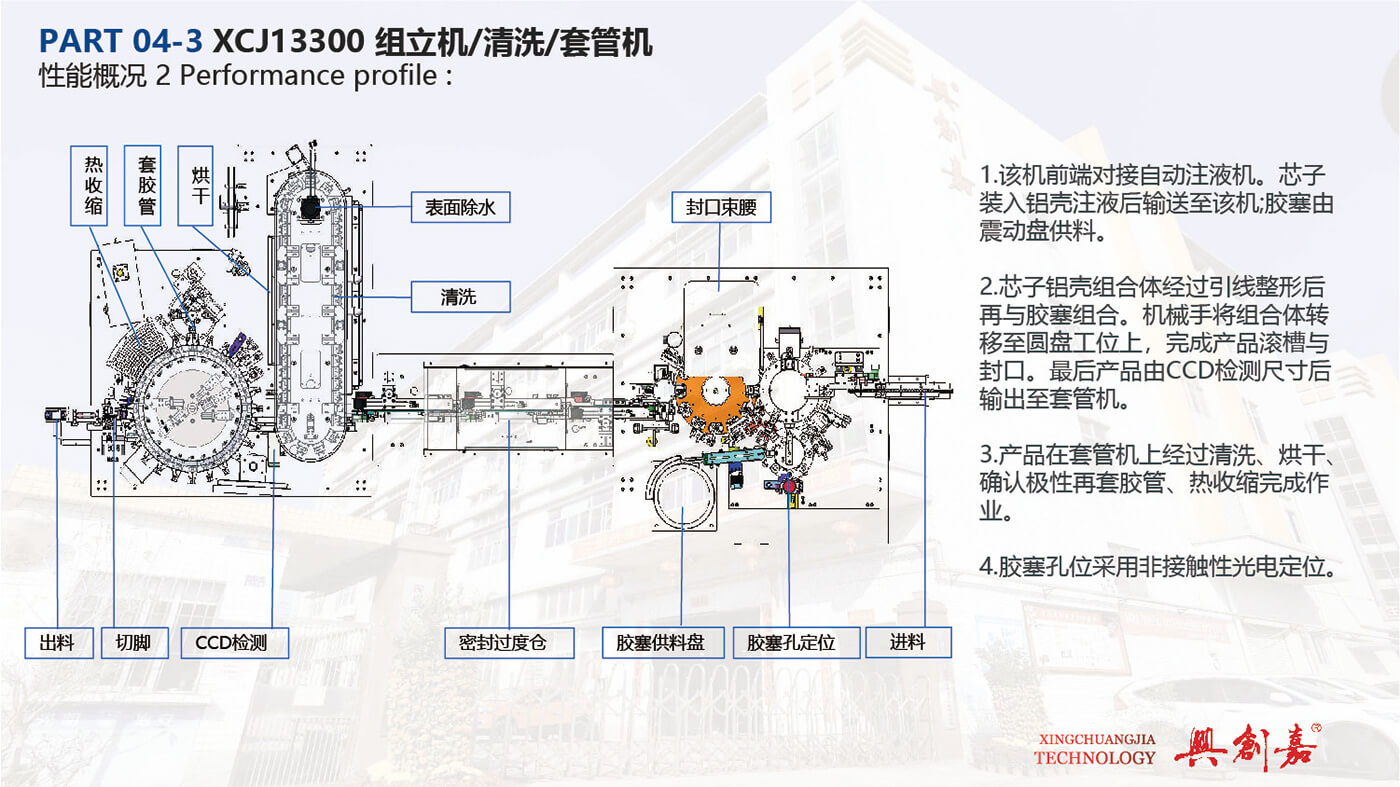

Lead TypeXCJ600DF Nailing and winding machine XCJ988/989 Liquid injection machine XCJ13300 Liquid injection machine XCJ13300 Assembly machine/cleaning/casing machine XCJ2500QX5 Washing machine XCJ880T Automatic Casing Machine XCJ880LT Modular casing machine XCJ1200TB Casing machine XCJTK Automatic casing machine

- Battery Production Equipment

-

Aluminum Electrolytic Capacitor Production Equipment

Language

Language

CN

CN

Home 》

Home 》

Service hotline

Service hotline WeChat Service Account

WeChat Service Account  WeChat Public Account

WeChat Public Account  Official Website

Official Website  Tik Tok

Tik Tok  Video Number

Video Number