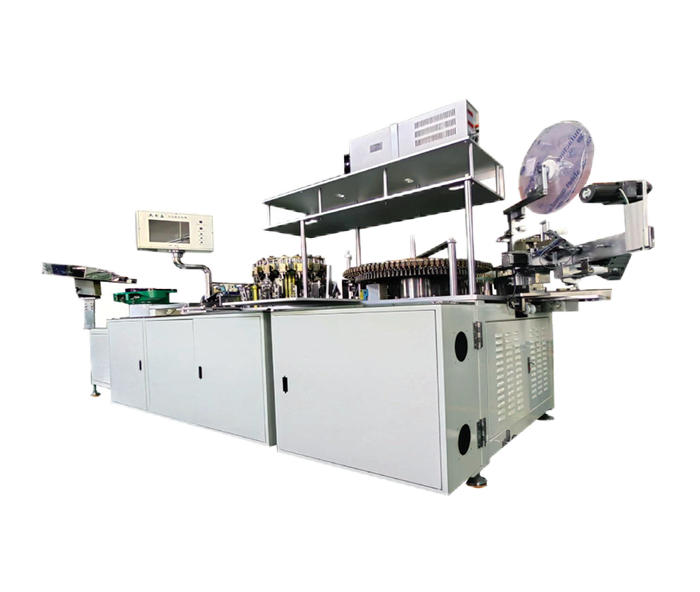

1. The products are transported horizontally through a vibrating tray. After adjusting the electrode guide pins and pressing and installing a plate , the machine distinguishes the polarities based on the length of the guide pins, adjusts the products, and confirms the polarities of the products again. After the defective products are eliminated, the machine confirms the polarity of the product again and then cuts the guide pins to ensure that no reverse polarity products escaped.

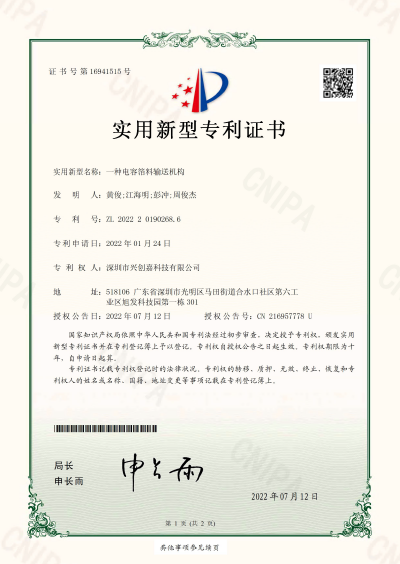

2. The feeding device adopts a toothless slider, which makes it easier to slide and reduces the force of the gripping of the products, reducing the risk of product damage or affecting performance while gripping and moving the products.

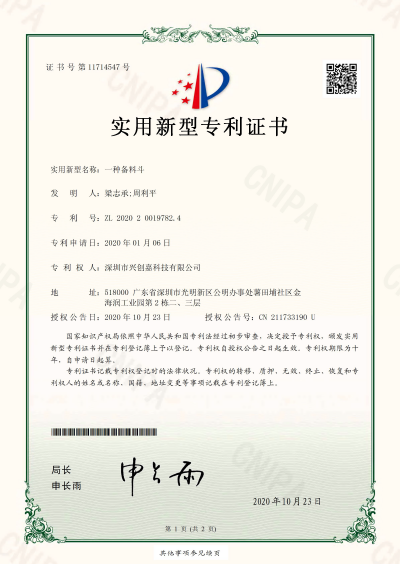

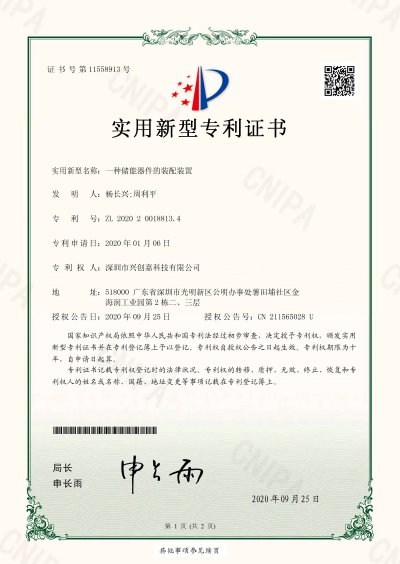

3. Both semi-finished products and seat plates are equipped with storage devices, which can automatically replenish materials when the vibration tray running out of materials gradually.

4. The main disc is designed with 16 stations. The machine completes the pressing and installation of the product seat plate twice , tests the capacity, loss, ESR (optional), and confirms the key dimensions of the seat plate and core lead wires through CCD inspection, and eliminates any defects.

5. 16 stationed disc using mechanical parallel clamp to obtain products, clamping material stability, not easy to wear.

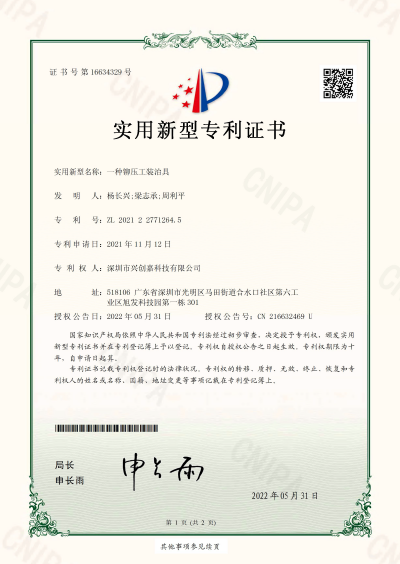

6. Press lead molding mode for the whole module design, thickness limit and lead positioning function, positive and negative lead thickness is consistent, before and after, left and right separate adjustment, adjustment is convenient; The die head is designed with tungsten steel, and the service life is long.

Language

Language

CN

CN

Home 》

Home 》

Service hotline

Service hotline WeChat Service Account

WeChat Service Account  WeChat Public Account

WeChat Public Account  Official Website

Official Website  Tik Tok

Tik Tok  Video Number

Video Number