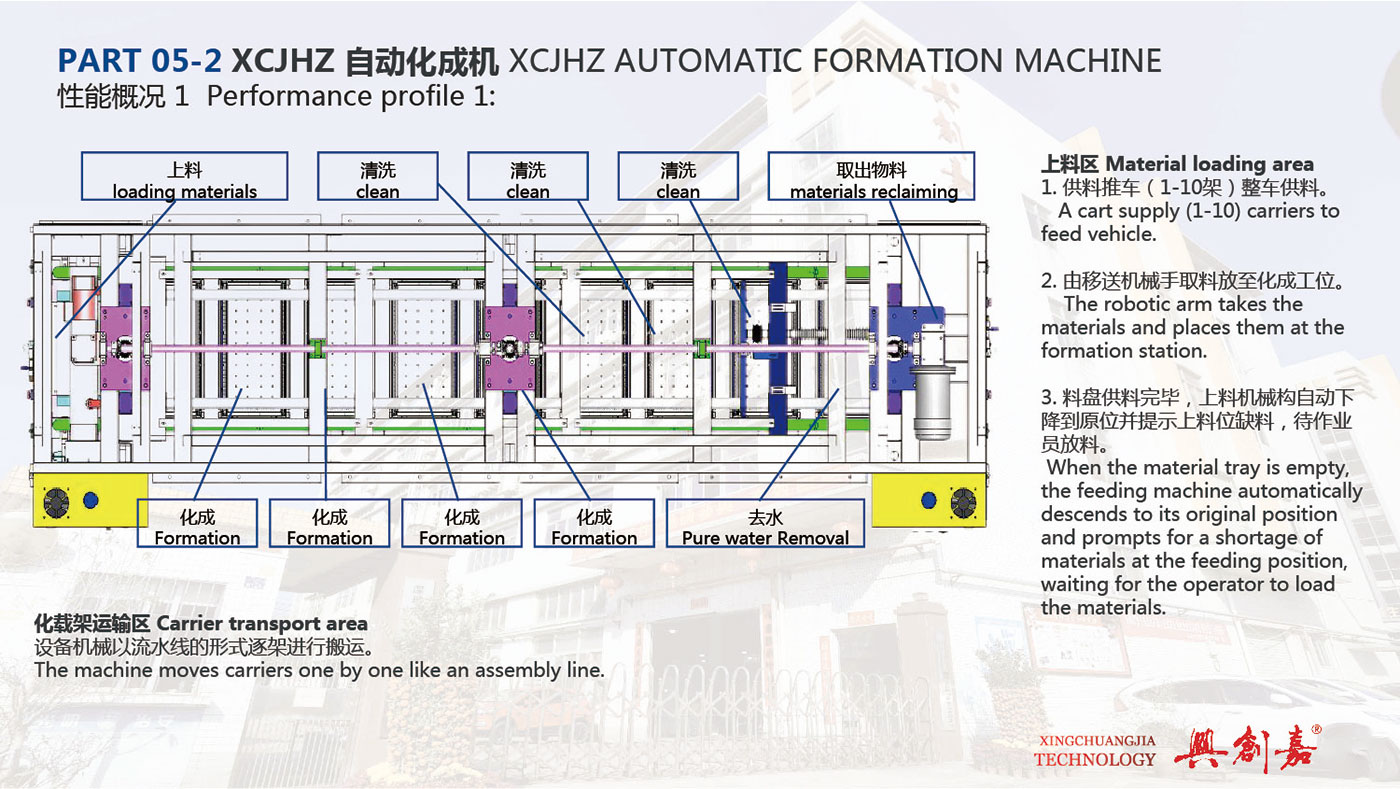

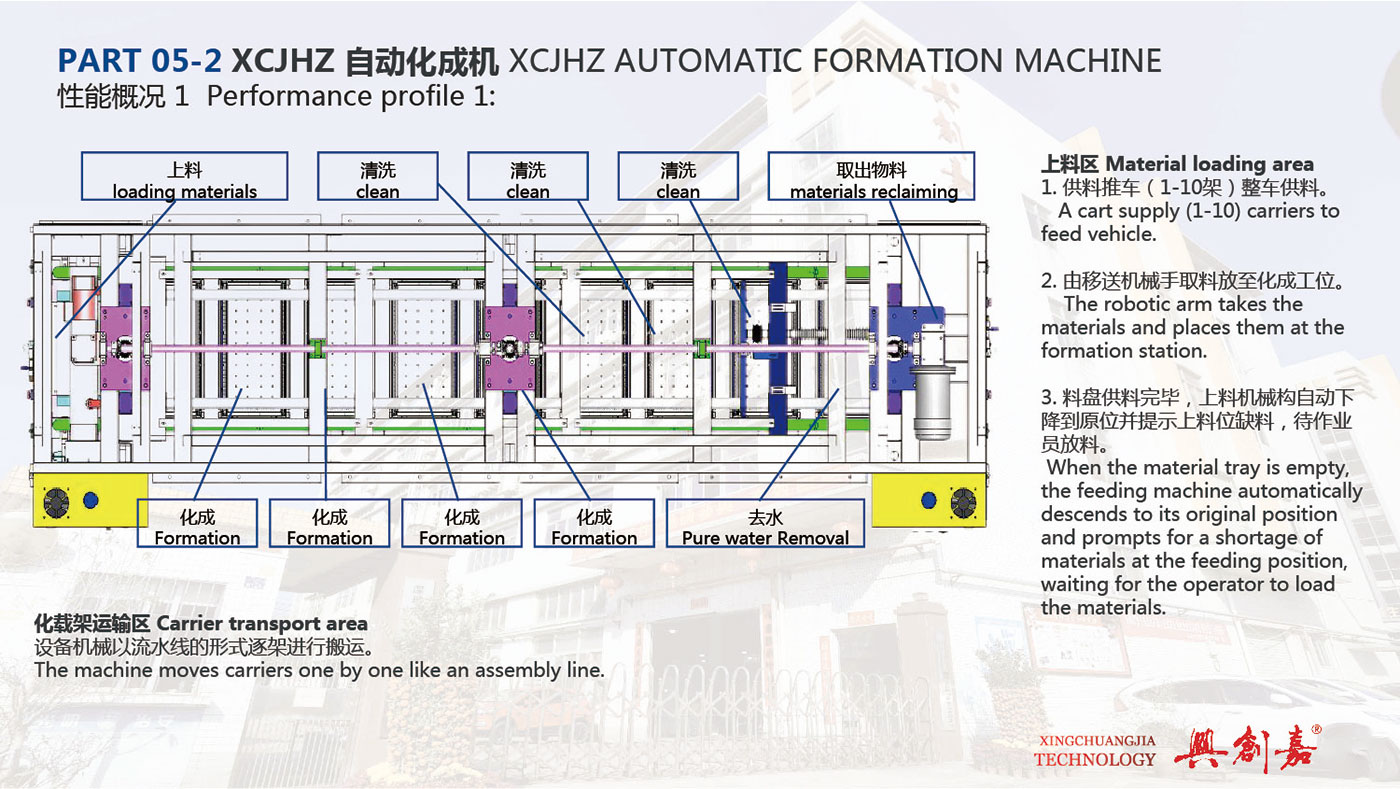

Material loading area

1. A cart supply (1-10) carriers to feed vehicle.

2. The robotic arm takes the materials and places them at the formation station.

3. When the material tray is empty, the feeding machine automatically descends to its original position and prompts for a shortage of materials at the feeding position, waiting for the operator to load the materials.

Carrier transport area

The machine moves carriers one by one like an assembly line.

Formation site

1. The material for the formation parts :SUS304.

2. Ascending of the material rack :The servo motor drives the vertical lifting and lowering of the material

carriers. The ascending and lowering speeds, positions, and time of the carriers are adjusted on the human-machine interface.

3. Liquid level control mode:Two ends overflowing type, with a manual valve at the inlet to regulate the liquid flow rate

4. Each formation tank is powered by a separate power supply. The parameters such as voltage, current, and time are displayed or set on the human-machine interface, and can also be automatically stored as process formulas.

5. The material of the formation water tank is SUS304, with 1/2/3/tank sharing one tank, and 4/5/6/tank sharing one tank, which is transported by a magnetic pump.

6. A filtering device is installed in the path of the forming agent returning to the tank.

7. Agent temperature: adjustable from room temperature to 90℃ with real-time monitoring.

8. Formation tank capacity:55L.

9. Formation sampling voltage : load end.

10. Electromagnetic valve control for formation tank replenishment.

11. Direct discharge of waste agent.

Language

Language

CN

CN

Home 》

Home 》

Service hotline

Service hotline WeChat Service Account

WeChat Service Account  WeChat Public Account

WeChat Public Account  Official Website

Official Website  Tik Tok

Tik Tok  Video Number

Video Number